CHARFANE has always been adhering to the corporate philosophy of "manufacturing with heart, customer first" since its establishment, and is committed to intelligent sewing machinery products and services, as well as providing users with professional overall solutions.

Behind each customer's good experience,

It is the research and development personnel's hard work on the product.

In response to the ever-changing market demand, relying on solid product strength and strong technical support, CHARFANE fully automatic elastic joint machine stands out among similar products through the perfect integration of production technology and sewing technology innovation, and has won many awards. User unanimous praise!

What is so good about the CHARFANE fully automatic rubber band machine?

Follow me to look down!

Industrial Internet of Things Technology

1.It can realize remote data update and system iteration, and maintain the optimal state of equipment software;

2. Support remote modification of parameters, cloud maintenance of equipment failure, greatly improve the efficiency of after-sales service, and truly realize the experience of extremely fast after-sales service.

3. You can view equipment data (working hours, machine output, etc.), operating status, and realize fast data interaction through the mobile APP interconnection.

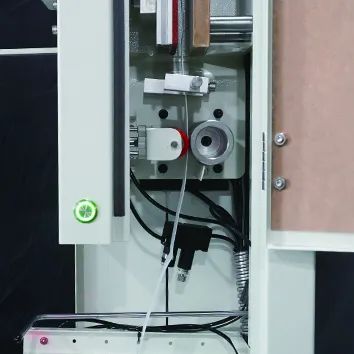

Industry top electrical configuration

Imported SMC electrical accessories are used to run faster and provide better stability and durability.

Equipped with LOGO positioning function

Through the color positioning system, single or multiple LOGO positions can be precisely positioned to effectively improve product quality.

Increase the infrared induction of the elastic stereotypes chamber

The specially designed elastic shaping chamber can effectively remove the folding marks of raw materials, and the finished products are more beautiful. At the same time, an infrared sensing device is added to avoid deformation of the elastic band due to excessive tension during the feeding process.

Automated functions for no human intervention

1. Automatic alarm and stop function for disconnection and bottom line.

2. The automatic feeder can set the quantity of each bundle according to the demand, and supports long-term automatic sewing.

3. Intelligently control the length of the elastic ring to reduce the error during measurement, and there is no need to modify the length twice after one setting.

4. The added automatic sensing device eliminates the continuous feeding failure when the upper thread is cut continuously and saves material waste.

5. The joints of the rubber band can be automatically sensed and removed, saving materials and improving time efficiency, and at the same time protecting the cutter.

Take innovation as the forerunner

Relying on products

Service as the core